Printed Circuit Board Assembly (PCBA) Overview-FASTPCBA

pcba15@fastpcba.cn

Printed circuit boards (PCBs) are fundamental components of electronic devices and are deeply integrated into all aspects of our lives. Whether it is household appliances, computers, digital devices used in daily life, or medical electrical equipment, military equipment in professional fields, almost all electrical equipment cannot function without them. After the PCB is fabricated, electronic components are precisely assembled onto it to form a PCBA that can be used in electronic products. The PCB assembly prototype is a trial production stage before the mass production of PCBA, and its main function is to comprehensively test the performance and reliability of the circuit board. With the continuous upgrading of electronic devices towards high performance, miniaturization, and intelligence, the demand for PCB assembly prototypes is also increasing day by day.

In terms of the current situation of PCB assembly:

Problems faced by European and American customers:

There are a limited number of local PCB manufacturers in Europe and America, which are struggling to meet the rapidly growing market demand. Moreover, there are very few manufacturers that can provide one-stop PCB assembly services. This directly leads to European and American customers facing difficulties such as high costs and long delivery times when producing PCB assembly prototypes. If they conduct PCB assembly in their own countries, not only will the material procurement costs be high, but also the labor costs and production process connection costs will increase significantly, thus consuming more money and time.

Language and cultural differences also add many obstacles for European and American customers to carry out PCB assembly business abroad. Although many foreign trade companies claim to be able to provide PCB assembly services, there is a scarcity of professionals who are proficient in both foreign languages and PCB manufacturing technologies. This makes it difficult for European and American customers to screen suitable PCB manufacturers, often requiring a lot of effort in communication and identification to find a partner that meets their needs.

The trend of one-stop service in China:

In order to follow the trend of market development, meet the increasingly diverse needs of customers, and enhance their own market competitiveness, many PCB assembly manufacturers in China actively provide one-stop services (Turnkey service) to domestic and international customers. Among them, FASTPCBA stands out with its outstanding strength. As a professional and highly influential PCB manufacturer, it can provide European and American customers with a one-stop, full-process service from PCB manufacturing, component procurement, PCB assembly to comprehensive testing.

Advantages of FASTPCBA:

Efficient production process: FASTPCBA has an independently developed intelligent production scheduling system. This system uses advanced algorithms to accurately schedule production tasks based on the urgency of orders, the complexity of products, and the idle status of equipment. This enables the efficient completion of PCB prototype production within just 12 hours, and the fastest delivery of PCB assembly prototypes within 7 hours, greatly shortening the delivery cycle and providing strong support for customers to seize market opportunities. At the same time, by introducing the concept of Industry 4.0 in the production process, the interconnection and automatic control of production equipment are realized, effectively reducing errors caused by human factors and greatly improving the stability of product quality.

Powerful supply chain integration ability: In the component procurement process, FASTPCBA has established long-term and stable cooperative relationships with more than 500 high-quality suppliers worldwide, covering various well-known brands of electronic components. With its large procurement scale and good cooperation reputation, it can not only ensure the high quality of the purchased components but also obtain extremely competitive prices. This enables customers to obtain high-quality PCBA products while effectively controlling costs. In addition, FASTPCBA has a strict supplier evaluation and management system that regularly conducts comprehensive evaluations of suppliers' product quality, delivery time, and service level to ensure the stability and reliability of the supply chain.

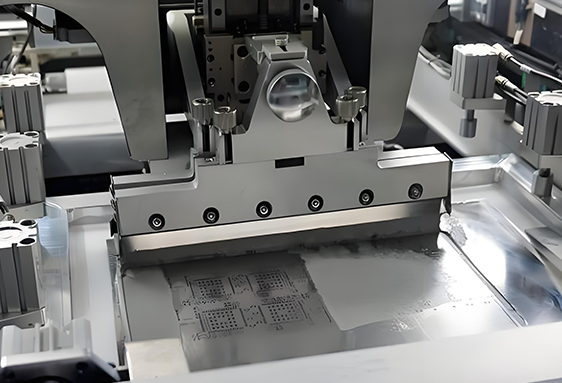

Professional technical team: FASTPCBA has gathered a group of senior engineers who have been deeply involved in the field of PCB manufacturing and assembly for many years. Team members all have rich industry experience and solid professional knowledge. In the PCB design stage, engineers can use advanced design software to optimize the design according to customers' needs and product application scenarios, ensuring that the electrical performance, heat dissipation performance, and manufacturability of the circuit board reach the best state. In the assembly process, engineers are proficient in various advanced assembly processes, such as high-precision SMT (Surface Mount Technology), complex BGA (Ball Grid Array) soldering, etc., and can accurately assemble electronic components onto the PCB. At the same time, the team is also equipped with professional test engineers who use a variety of advanced testing equipment and methods, such as X-Ray detection, flying probe testing, etc., to conduct comprehensive and detailed inspections of PCBA to ensure that the product quality meets international standards.

High-quality customer service: FASTPCBA always adheres to the "customer first" service concept and provides customers with comprehensive and considerate services. The company has established a dedicated customer service team that is available 24/7 to respond to customers' inquiries and needs. Whether it is technical communication and scheme design in the early stage of the project, progress tracking and problem feedback during the production process, or product maintenance and technical support after sales, the customer service team can provide professional solutions in a timely manner. In addition, the sales staff of FASTPCBA have received strict professional knowledge training in PCB manufacturing. They can not only accurately understand customers' needs but also communicate and exchange with customers at a technical level, providing professional suggestions and guidance, effectively solving the communication barriers between sales and customers at the technical level.

The one-stop service greatly reduces the time and effort that customers spend on separately connecting with multiple suppliers for different steps in the PCB assembly manufacturing process. Its scientific order arrangement system enables customers to obtain higher-quality PCB assembly products at lower costs and in a shorter time, and there is no minimum order quantity limit. Customers can flexibly choose the individual combination of PCB manufacturing, component procurement, and PCB assembly services according to their actual needs.

Advanced equipment, high-quality materials, experienced engineers, and on-time delivery are important signs of an excellent one-stop PCB manufacturer. As a PCB prototype manufacturer with rich experience in one-stop service in the PCB assembly field, FASTPCBA can rely on its many advantages to provide highly cost-effective solutions for different customers' diverse needs and consistently ensure product quality.

Get in touch with us and get started on a PCB Assembly services at sales08@pcb-smt.net today.