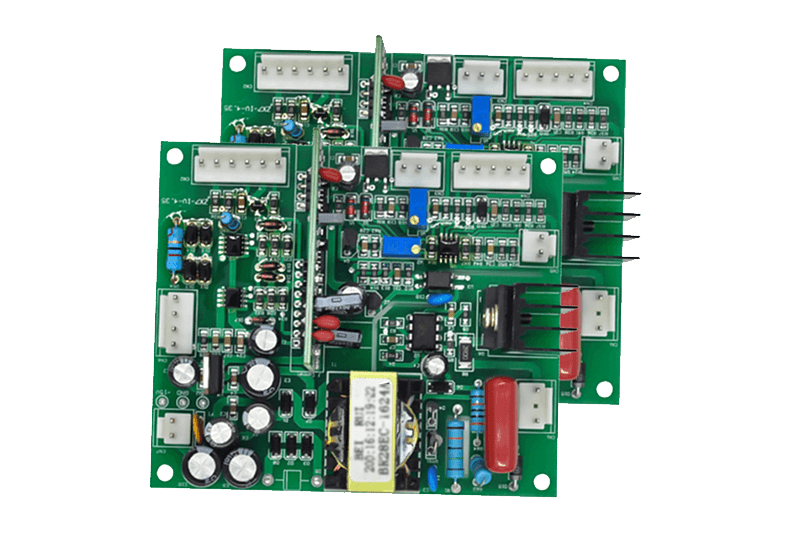

PCB ASSEMBLY MANUFACTURER

CNPCBA is a real PCB assembly manufacturer in Shenzhen, which has three manufacturing bases equipped with the most advanced production equipment such as YAMAHA pick and place machine, Reflow oven, Wave soldering Machine, X-RAY, AOI testing machine and the most professional technical personnel.

PCB Assembly Manufacturer

FASTPCBA is a real PCB assembly manufacturer in Shenzhen. It has three manufacturing bases, equipped with the most advanced production equipment such as YAMAHA pick - and - place machines, reflow soldering ovens, wave soldering machines, X - RAY machines, AOI testing machines and staffed with the most professional technicians.

PCB assembly capabilities of FASTPCBA

PCB Assembly Applications

Automotive Electronics Field

● Powertrain System Control: The engine control unit (ECU) achieves precise control of the engine through PCBA assembly, including fuel injection, ignition timing, speed regulation, etc. This ensures the engine operates efficiently and stably, improving the vehicle's power performance and fuel economy.

● Safety Systems: The PCBA assembly of key automotive safety systems such as the airbag control module, anti-lock braking system (ABS), and electronic stability program (ESP) can monitor the vehicle's status in real time and respond promptly in emergency situations to ensure the safety of drivers and passengers.

● Infotainment Systems: The realization of functions such as in-car navigation, multimedia playback, Bluetooth connection, and vehicle information display depends on PCBA assembly. This provides drivers and passengers with a wealth of entertainment and information services, enhancing the driving experience.

Consumer Electronics Field

● Smartphones and Tablets: PCB assembly is a core component. It integrates numerous components such as processors, memories, communication modules, and sensors, enabling powerful computing, communication, entertainment, and other functions to meet people's daily work, study, and life needs.

● Smart Wearable Devices: Such as smart watches and fitness trackers. Through PCBA assembly, precise sensor data collection and processing, as well as wireless communication functions like Bluetooth and Wi-Fi, are achieved. They can monitor health data in real time, receive notifications, control other smart devices, and so on.

● Smart Home Devices: This includes smart speakers, smart light bulbs, smart sockets, smart door locks, smart cameras, etc. Relying on PCBA assembly to connect to the home network, they can realize functions such as remote control, automated scene setting, and data interaction, enhancing the convenience, comfort, and security of home life.

Industrial Control Field

● Automated Production Equipment: The PCBA assembly in equipment such as industrial robots, CNC machine tools, and automated production lines is responsible for controlling the movement of the equipment, processing accuracy, and coordination of the production process. This improves industrial production efficiency, quality, and stability, enabling intelligent manufacturing.

● Industrial Sensors and Monitoring Equipment: Industrial sensors such as temperature sensors, pressure sensors, and flow sensors, as well as environmental monitoring equipment and equipment condition monitoring systems, rely on PCBA assembly to achieve signal acquisition, processing, and transmission. This provides crucial data support for industrial production process control and equipment maintenance.

Medical Electronics Field

● Medical Diagnostic Equipment: High-precision signal acquisition, processing, and imaging functions of medical diagnostic equipment such as electrocardiogram (ECG) machines, electroencephalogram (EEG) machines, ultrasonic diagnostic equipment, CT scanners, and magnetic resonance imaging (MRI) devices rely on PCBA assembly. This assists doctors in accurately diagnosing diseases.

● Medical Treatment Equipment: The PCBA assembly of medical treatment equipment such as pacemakers, defibrillators, electronic syringes, high-frequency electrosurgical knives, and laser treatment devices ensures that the equipment outputs precise treatment energy and parameters, enabling effective treatment of diseases and safeguarding patients' lives and health.

● Medical Monitoring Equipment: Medical monitoring equipment such as patient monitors, blood glucose monitors, blood pressure monitors, and blood oxygen saturation monitors can achieve real-time and continuous monitoring of physiological parameters through PCBA assembly. This helps to detect abnormal vital signs of patients in a timely manner and provides important basis for medical treatment.

Communication Equipment Field

● Base Station Equipment: The PCBA assembly of key devices such as transceivers and baseband processing units in communication base stations like 5G and 4G base stations enables functions such as signal transmission, reception, modulation and demodulation, and signal processing, ensuring the coverage and signal quality of the communication network.

● Network Communication Equipment: The PCBA assembly of network communication equipment such as routers, switches, and modems is responsible for network data transmission, switching, and routing selection. It builds a stable and efficient communication network to meet the network communication needs of enterprises and home users.

Aerospace and Defense Field

● Avionics Systems: The PCBA assembly of avionics systems in aircraft, such as flight control systems, navigation systems, communication systems, and radar systems, is required to have high reliability, anti-interference capabilities, and stability to ensure the safe flight of the aircraft in complex environments.

● Spacecraft Electronics Equipment: The PCBA assembly of electronic equipment in spacecraft such as satellites and rockets, including satellite communication payloads, attitude control systems, and power management systems, needs to adapt to extreme space environments to ensure the smooth progress of space missions.

● Defense and Military Equipment: The PCBA assembly in defense and military equipment such as radars, missiles, communication radios, and electronic warfare equipment has extremely high requirements for performance, reliability, and confidentiality, providing key technical support for national defense security.

Power and Energy Field

● Monitoring and Control of Power Equipment: The PCBA assembly of equipment such as relay protection devices in substations, power monitoring instruments, smart meters in smart grids, and distribution automation terminals enables real-time monitoring, fault diagnosis, and control of the operating status of the power system, ensuring the safe and stable operation of the power system.

● New Energy Power Generation Systems: The PCBA assembly in new energy power generation equipment such as solar photovoltaic inverters and wind turbine converters is responsible for converting clean energy such as solar and wind energy into stable electrical energy and connecting it to the grid, promoting the development of the new energy industry.

Internet of Things (IoT) Field

● Smart Sensor Nodes: Smart sensor nodes in various IoT applications, such as environmental monitoring sensors, industrial IoT sensors, and agricultural IoT sensors, achieve data collection, processing, and wireless transmission through PCBA assembly, connecting the physical world with the digital world.

● IoT Gateways and Edge Computing Devices: IoT gateways are responsible for connecting different types of sensor networks to the Internet, and edge computing devices perform data processing and analysis at the edge close to the data source. Their PCBA assembly provides crucial support for the aggregation, processing, and transmission of IoT data, driving the development of IoT applications.

If you are interested in PCBA assembly, please feel free to contact our customer service via email. We will provide you with high-quality PCB assembly services backed by extensive experience and top-notch precision equipment.

Regardless of the type of PCB, PCBA requirements, whether it's a small batch or a large quantity, simply send us your Gerber and BOM files, along with your material and quantity requirements. We will send you a quotation promptly.

What are the differences between PCB and PCBA?

PCB, namely Printed Circuit Board, mainly provides electrical connections and physical support for electronic components. It is composed of substrate materials, conductive layers, insulating layers, and protective layers. Its manufacturing process encompasses multiple steps such as design, material cutting, drilling, electroplating, and etching.

PCBA, based on the PCB, is a complete functional assembly formed by assembling various electronic components through methods like soldering and plugging, and then undergoing debugging and testing. It not only includes all the components of the PCB but also active devices (such as chips), passive devices (such as resistors and capacitors), and connection devices. The manufacturing of PCBA requires PCB processing first, followed by processes such as solder paste printing, component placement, reflow soldering, plug-in, wave soldering, and testing in sequence. Compared with PCB manufacturing, PCBA manufacturing is more complex, aiming to produce functional modules that can be directly used in electronic products.

Are you ready to start getting a quote?

If you want to have PCBA assembly & SMT placement done, simply upload your Gerber and BOM files to our website: www.cnpcba.com. We promise to deliver within 24 hours, with free shipping!