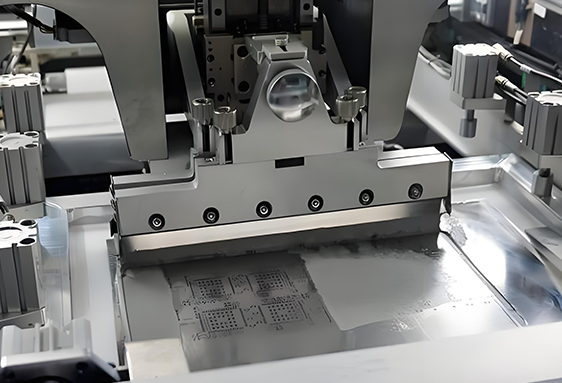

Analysis and Solutions for Solder Paste Printing Defects in SMT Assembly

pcba15@fastpcba.cn

Core Causes and FASTPCBA's Solutions

Stencil Design Flaws

- Issue: Aperture accuracy deviations (>±15μm) and rough via walls (Ra >1.2μm) lead to uneven paste transfer.

- Solution: AI-driven stencil design with laser-cut + nano-coating technology, achieving ±5μm accuracy and Ra <0.8μm.

Process Parameter Mismatch

- Issue: Excessive squeegee pressure (e.g., 60N/cm) causes paste leakage.

- Solution: Dynamic pressure control (20-50N/cm) and adaptive speed adjustment (15-40mm/s).

Environmental Instability

- Issue: Humidity >70% accelerates paste slump.

- Solution: Closed-loop humidity control (50±5% RH) and vacuum PCB storage systems.

FASTPCBA's Industry Impact

- Automotive Client: Reduced bridging defects by 96% through stencil optimization and parameter tuning.

- Consumer Electronics Client: Slashed insufficient solder defects from 15% to 2% via Type 4 paste and automated cleaning.

FAQ

Q: How does FASTPCBA ensure long-term process stability?

A: Our IoT-enabled real-time monitoring system tracks 50+ parameters (e.g., paste viscosity, pressure curves) and auto-adjusts every 0.5 seconds.

Q: What certifications support your solutions?

A: All processes comply with IPC-7525 stencil standards and IATF 16949 automotive-grade quality protocols.

Q: Can existing SMT lines integrate your system?

A: Yes. Our modular upgrades require <24hrs downtime and are compatible with ASM, Fuji, and Panasonic equipment.

About FASTPCBA

FASTPCBA specializes in precision electronics manufacturing for automotive, medical, and 5G industries. With 36 fully automated SMT lines in Shenzhen, we deliver 98.5% first-pass yield and 48-hour rapid prototyping.

Contact

📞 +86 755 2345 6789

🌐 www.cnpcba.com