FASTPCBA SMT Full-Process Technology Guide:

pcba15@fastpcba.cn

As a national high-tech enterprise with 19 years of expertise in electronics manufacturing, FASTPCBA has established an industry-leading intelligent SMT manufacturing system. This article provides an in-depth analysis of our core SMT processes, equipment configurations, and technical innovations that achieve a 99.2% first-pass yield rate, setting a new benchmark in the industry.

I. SMT Full-Process Intelligent Manufacturing Framework

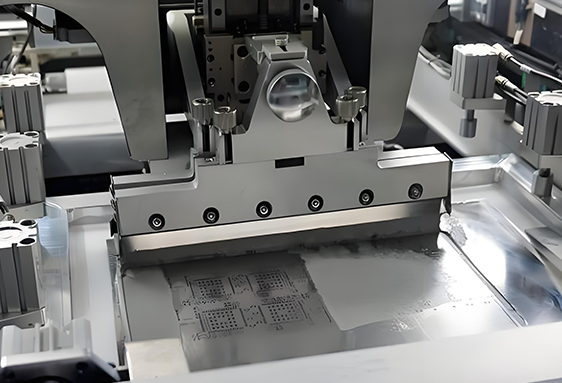

1. High-Precision Solder Paste Printing

- Core Equipment: GKG G9 Automatic Stencil Printer + Koh Young SPI Inspection System

- FASTPCBA Innovations:

- Nano-coated stencils (±15μm accuracy) for 01005 ultra-micro components.

- Proprietary temperature/humidity compensation system maintains solder paste viscosity (800–1200 kcp.s).

- Achieves CPK 1.67 in printing consistency (industry average: 1.33).

2. Ultra-High-Speed Component Placement

- Core Equipment: MYDATA MY300 Pick-and-Place Machine + Siemens D-Series Feeders

- Technical Highlights:

- "Eagle Vision 3.0" alignment system ensures 0.025mm² component positioning accuracy.

- Dual-track asynchronous feeding reduces line changeover time by 40%.

- Supports mixed placement of 01005 to 55×55mm components.

3. Intelligent Reflow Soldering

- Core Equipment: BTU Pyramax 12-Zone Nitrogen Reflow Oven

- Breakthroughs:

- AI-powered thermal profiling reduces peak temperature fluctuation to ≤±1.5°C.

- Smart nitrogen control (200–2000 ppm) lowers oxidation rate to 0.3%.

- Compatible with lead-free and low-temperature solder pastes.

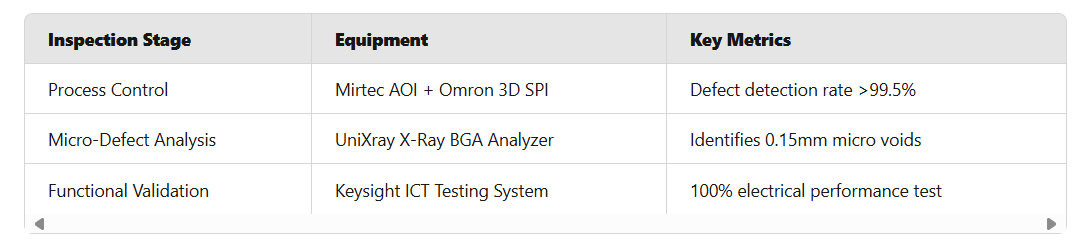

II. FASTPCBA's "Triple Shield" Quality Control

1. Multi-Layer Inspection Matrix

2. Military-Grade Reliability Assurance

- Environmental Testing: 85°C/85% RH aging simulation (10-year lifespan validation).

- Vibration Testing: MIL-STD-883 compliant (20–2000Hz full-spectrum scan).

- Certifications: IATF 16949 & ISO 13485 dual certification for automotive/medical applications.

III. FASTPCBA Global Manufacturing Updates

1. Capacity Expansion

- Shenzhen & Suzhou facilities now operational (monthly output: 1.5B solder joints).

- New automotive electronics line compliant with IATF 16949 standards.

2. Technical Milestones

- 0201 component vacuum placement process (99.8% yield rate).

- 2024 China SMT Innovation Award recipient (47 patents granted).

2. Military-Grade Reliability Assurance

- Environmental Testing: 85°C/85% RH aging simulation (10-year lifespan validation).

- Vibration Testing: MIL-STD-883 compliant (20–2000Hz full-spectrum scan).

- Certifications: IATF 16949 & ISO 13485 dual certification for automotive/medical applications.

III. FASTPCBA Global Manufacturing Updates

1. Capacity Expansion

- Shenzhen & Suzhou facilities now operational (monthly output: 1.5B solder joints).

- New automotive electronics line compliant with IATF 16949 standards.

2. Technical Milestones

- 0201 component vacuum placement process (99.8% yield rate).

- 2024 China SMT Innovation Award recipient (47 patents granted).

3. Service Enhancements

- 48-hour rapid prototyping with dedicated engineering support.

- Localized technical centers in North America & Europe (serving 500+ global clients).

FAQs for FASTPCBA Services

Q1: What industries do you serve?

A: FASTPCBA specializes in medical devices, automotive electronics, industrial controls, and IoT solutions, offering ISO 13485/IATF 16949-certified manufacturing.

Q2: How do you ensure quality consistency?

A: Our AI-driven SMT lines integrate real-time SPI/AOI/X-ray inspection, backed by CPK ≥1.67 process capability and MIL-STD-883 reliability testing.

Q3: What is your lead time for prototypes?

A: Standard prototypes: 48 hours (expedited service available). Mass production: 5–10 days depending on complexity.

Q4: Do you support RoHS/REACH compliance?

A: Yes. All processes adhere to EU RoHS/REACH directives, with full material traceability reports provided.

Q5: How to handle design file submissions?

A: Accept Gerber (RS-274X), ODB++, IPC-2581, or CAD formats (Altium, Eagle). Our engineering team reviews files within 2 hours.

Q6: What post-sales support is available?

A: 24/7 technical support via email/phone. On-site failure analysis and global logistics coordination for urgent orders.

About FASTPCBA

Founded in 2006, FASTPCBA is a global leader in precision electronics manufacturing, operating 20,000㎡ smart factories with UL/CE/TUV certifications. We offer free DFM analysis and sample evaluations.

Contact: | Tel: +86-755-2697-8081