What is SMT Assembly?SMT Assembly Capabilities of FASTPCBA

pcba15@fastpcba.cn

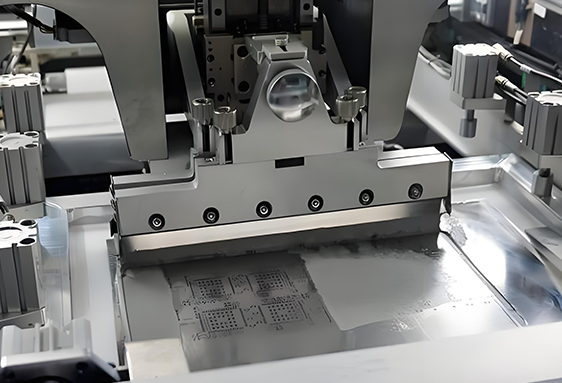

SMT (Surface Mount Technology) is a surface mount technology. It is an electronic assembly technology that directly mounts surface mount components (abbreviated as SMC/SMD, also known as chip components in Chinese) without pins or with short leads onto the surface of the printed circuit board (PCB) or at the specified positions on the surface of other substrates, and then conducts welding and assembly through methods like reflow soldering. It has replaced the traditional through-hole mounting technology and become an extremely important assembly method in modern electronics manufacturing, widely used in the production and manufacturing of various electronic products, such as smartphones, computers, and household applian

SMT Assembly Capabilities

High-Speed Mounting: Advanced SMT placement machines can achieve extremely high mounting speeds. Taking a common high-speed placement machine as an example, it can mount more than 50,000 components per hour, greatly improving production efficiency and meeting the needs of large-scale production.

High-Precision Mounting: The mounting precision of placement machines can reach ±0.03mm or even higher. This enables tiny components, such as resistors and capacitors with a 01005 package (with a size of 0.4mm × 0.2mm), to be accurately mounted onto the PCB board, ensuring the high performance and stability of electronic products.

Compatibility with Diverse Components: SMT assembly equipment can be compatible with various types of components, including common resistors, capacitors, inductors, integrated circuits (ICs), and can also handle complex packaging forms of components such as ball grid array (BGA) packaging and chip-scale packaging (CSP). For example, in the SMT assembly of a mobile phone motherboard, hundreds of different types and packaging forms of components may be involved.

Advantages of SMT Assembly

Small Size and Light Weight: Compared with the traditional through-hole mounting technology, SMT assembly can reduce the volume of the PCB by approximately 30% - 50% and the weight by approximately 20% - 60%. This is because SMT components do not need to be drilled and installed on the PCB like through-hole components, saving a lot of space. Meanwhile, it enables electronic products to achieve miniaturization and lightweight design, such as thin and light laptops and smartphones.

High Reliability: Since the SMT assembly process is highly automated, it reduces the uncertainties brought by manual operations. The high-precision operation of SMT equipment makes the quality of solder joints more reliable and reduces the occurrence probability of defects such as false soldering and missing soldering. The defect rate of manual assembly is usually between 0.5% and 2%. After adopting the SMT assembly process, the defect rate can be reduced to 0.05% - 0.2%. In addition, the connection method between SMT components and the PCB is more stable and can better adapt to complex environments such as vibration and impact, improving the reliability and stability of electronic products.

Significant Cost Benefits: Although the initial investment in SMT equipment is relatively large, its advantages are obvious in the long-term and large-scale production. On the one hand, automated SMT production lines greatly improve production efficiency. A high-speed SMT production line can process more than 8,000 solder joints per hour, while manual work can only process approximately 200 - 400 solder joints per hour, greatly shortening the production cycle. On the other hand, SMT assembly reduces the dependence on manual labor, and labor costs can be reduced by approximately 30% - 50%. Meanwhile, the SMT process reduces the use of raw materials. For example, the amount of solder used is only 1/5 - 1/3 of that in through-hole mounting, thus reducing material costs by approximately 20% - 40%.

SMT Assembly Capabilities of FASTPCBA

Large-Scale Production Capacity: FASTPCBA has multiple fully automated SMT production lines and can complete the assembly of more than 500,000 square meters of PCBs every month, possessing a powerful large-scale production capacity to meet the batch order requirements of different customers.

High Precision and High Yield Rate: In terms of high-precision mounting, the SMT equipment of FASTPCBA can achieve a mounting precision of ±0.025mm, ensuring the accurate installation of complex circuits and tiny components. With advanced equipment and a strict quality control system, the SMT assembly yield rate of FASTPCBA is stably above 99.8%, ensuring that high-quality products are provided to customers.

Diverse Services and Quick Response: Besides conventional SMT assembly, FASTPCBA can also provide diverse assembly services such as BGA assembly, mixed assembly of through-hole and SMT, etc. For customers' small-batch orders and urgent orders, FASTPCBA has the ability to respond quickly and can complete the delivery of small-batch samples within 48 hours, helping customers quickly promote the R&D and market launch process of products.

Get in touch with us and get started on a PCB Assembly services at sales08@pcb-smt.net today.