Optimizing SMT Processes for Enhanced Efficiency and Quality - FASTPCBA

pcba15@fastpcba.cn

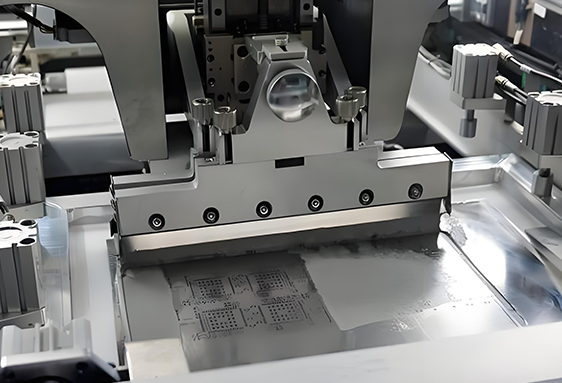

In the field of electronics manufacturing, Jingbang Technology has significantly enhanced the production efficiency of Surface Mount Technology (SMT) through a series of specific strategies and technical methods. Initially, the company adopted advanced management models such as Lean Production and Six Sigma, using Value Stream Mapping to reduce waste and optimize processes . Furthermore, Jingbang introduced high-speed placement machines like FUJI CP6/CP8 and emphasized regular maintenance to ensure optimal performance .

In terms of process improvements, Jingbang utilized offline programming technology to enhance the flexibility of YAMAHA's SMT machines and implemented Automated Optical Inspection (AOI) systems to ensure product quality . Regarding material management, Jingbang stressed proper storage conditions for solder paste and standardized component brands and models to simplify inventory management .

Moreover, Jingbang places significant importance on employee training and development, encouraging continuous learning and implementing the "7S" management principles to create an efficient and orderly working environment . These measures have not only increased production speed and quality but also reduced costs, enhancing market competitiveness.