SMT Industry Development Status and Trend Insights

pcba15@fastpcba.cn

SMT Industry Development Status and Trend Insights

In the modern electronic manufacturing field, Surface Mount Technology (SMT) undoubtedly plays a pivotal role. It is not only a key technology for achieving miniaturization, lightweight, and high - performance of electronic products but also an important driving force for the continuous development of the electronics industry.

I. Global SMT Market Size and Growth Trend

According to the research data of QYResearch, the SMT market shows a steady growth trend globally. It is expected that by 2030, the global SMT market size will reach $9.33 billion, with a compound annual growth rate of 4.6%. Behind this growth trend is the continuous demand and promotion of SMT technology in numerous application fields.

II. Analysis of SMT Requirements in Major Application Fields

(1) Consumer Electronics Field

Consumer electronics has always been an important application area for SMT technology. Take smartphones as an example. With the continuous innovation of technology, the number of functional modules integrated inside mobile phones is increasing day by day, such as high - pixel cameras, under - screen fingerprint recognition, 5G communication modules, wireless charging, etc. The realization of these functions depends on SMT technology to precisely mount more and more tiny components in a limited space. Nowadays, the number of components on smartphone motherboards is increasing while their size is getting smaller. The precise mounting ability of SMT technology makes all these possible. Moreover, consumer electronics products such as tablets and wearable devices are also developing towards being thinner, lighter, and more intelligent, and the demand for SMT is also on the rise.

(2) Network Communication Field

The advent of the 5G era has completely changed the pattern of network communication. The large - scale deployment of 5G base stations and the rapid upgrading of communication equipment have put forward higher requirements for SMT technology. In 5G base stations, key components such as radio - frequency modules and base - band processing units need to have high performance and reliability. SMT technology can ensure the precise assembly of these components, meeting the strict requirements of 5G communication for signal transmission speed and stability. At the same time, with the booming development of the Internet of Things (IoT), the communication demand between various intelligent terminal devices and base stations has surged, which further promotes the application of SMT technology in the network communication field.

(3) Automotive Electronics Field

The trends of intelligence, electrification, and networking in the automotive industry have made automotive electronic systems increasingly complex. Advanced Driver - Assistance Systems (ADAS), in - vehicle infotainment systems, and battery management systems for electric vehicles all rely on the support of SMT technology. Taking the ADAS system as an example, components such as cameras, radars, and sensors included in it need to be precisely assembled on the circuit board through SMT technology to ensure that the system can accurately sense the surrounding environmental information and provide reliable assisted driving functions for drivers. The extremely high requirements for safety and reliability in automotive electronics have prompted the continuous improvement of SMT process quality and stability.

(4) Medical Equipment Field

In the medical equipment industry, SMT technology also plays an important role. The development of wearable medical devices, portable diagnostic devices, and implantable medical devices all depends on SMT technology to achieve miniaturization and intelligence. For example, implantable or long - worn medical devices such as pacemakers and insulin pumps need to integrate complex electronic components and circuits in a very small space. SMT technology can achieve high - precision mounting and reliable connection of these components, ensuring the stable operation of medical devices and the safety of patients.

III. Development Status of the Domestic SMT Market

As a major global production base for electronic products, China occupies an important position in the SMT field. Domestically, there are huge industrial clusters in consumer electronics, communication equipment, automotive electronics, etc., providing a broad space for the development of the SMT market.

In recent years, the domestic SMT industry has made remarkable progress in terms of technical level and production scale. On the one hand, more and more enterprises have introduced advanced SMT production equipment and process technologies, improving product quality and production efficiency. On the other hand, domestic enterprises have also continuously increased their investment in technology research and development and innovation. Through cooperation with universities and scientific research institutions, the localization development of SMT technology has been promoted.

However, the domestic SMT market also faces some challenges. With the intensification of market competition, enterprises need to continuously enhance their core competitiveness. While improving production efficiency and reducing costs, they should pay more attention to product quality and technological innovation.

IV. Services and Contributions of FASTPCBA in the SMT Field

In the development process of the domestic SMT industry, FASTPCBA has emerged and provided comprehensive and high - quality services for the industry.

(1) Advanced Manufacturing Capabilities

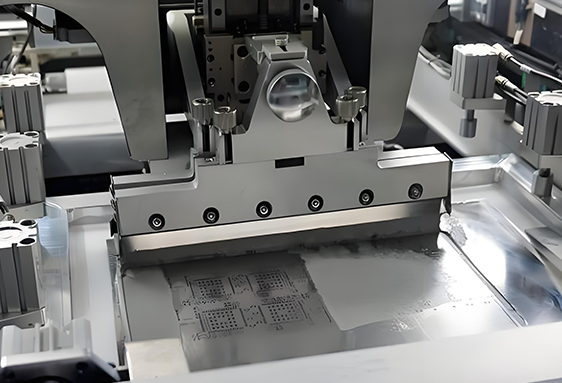

FASTPCBA is equipped with advanced equipment such as the MY500 solder paste jet printer imported from Sweden and the MYDATA Swedish fully - automatic SMT production line. It has a daily production capacity of 3 million points. Its advanced equipment and efficient production lines can meet the large - scale production needs of customers. At the same time, the equipment of FASTPCBA can achieve rapid line change - over and stencil - less solder paste printing, with an express delivery time of 4 hours, greatly improving production efficiency and saving time costs for customers.

(2) One - stop Service System

- PCB Manufacturing: FASTPCBA has advanced technologies such as laser direct imaging, high - frequency board manufacturing, characteristic impedance control, blind and buried via manufacturing, aluminum - based boards, and flying probe testing. It can produce various types of printed circuit boards, including single - sided boards, double - sided boards, multi - layer boards, HDI boards, etc., with a minimum size width/length of less than 30mm, which can meet the diverse needs of different customers for PCBs.

- Electronic Component Procurement Agency: FASTPCBA has a professional electronic component procurement team that can provide customers with high - quality and efficient component procurement services. Relying on rich industry experience and extensive supplier resources, the team ensures the reliable quality and stable supply of the purchased components, relieving customers of their worries about component procurement.

- SMT Assembly: In terms of SMT assembly, FASTPCBA can achieve high - precision component mounting with advanced equipment and exquisite craftsmanship. Whether it is 01005 and other small - sized chip components or fine - pitch Ball Grid Array (BGA), Chip - Scale Package (CSP), etc., FASTPCBA can ensure the accuracy and reliability of mounting.

- Testing and Assembly: FASTPCBA is equipped with strict quality control and testing equipment. After 9 "testing procedures" for strict inspection, it provides a variety of testing services, including ICT testing, FCT testing, AOI inspection, etc. Through these tests, problems that occur during the production process can be discovered and solved in a timely manner, ensuring that the delivered products meet high - standard quality requirements.

(3) Strong Technology Research, Development, and Innovation Capabilities

The R & D team of FASTPCBA has successfully developed a variety of production technologies, such as mechanical micro - holes, high - aspect - ratio holes, high - layer - count backplanes, high - precision impedance, HDI, etc., continuously enhancing the technical content and competitiveness of products. At the same time, through cooperation with customers from developed countries such as Japan and Germany, FASTPCBA actively introduces international advanced process technologies and management methods, and has formed characteristic services in high - difficulty and high - precision IC soldering, such as BGA chip rework and soldering.

(4) Strict Quality Control System

FASTPCBA strictly implements the IATF16949 certification for automotive electronics and the ISO13485 quality system standard for medical electronics, and has obtained the ISO9001 - 2000 quality management system certification. Through these strict quality control standards, FASTPCBA ensures that every link of the product, from raw material procurement, production processing to finished product delivery, meets international standards, providing customers with reliable products and services.

V. Prospects for the Development Trends of SMT Technology

(1) Continuous Deepening of Miniaturization and High - Density Trends

With the continuous upgrading of the pursuit of miniaturization and high - performance of electronic products, SMT technology will develop towards more miniaturization and higher density. In the future, smaller - sized and higher - integration components will continue to emerge, which will pose higher challenges to the accuracy and mounting ability of SMT equipment. At the same time, High - Density Interconnect (HDI) technology will be more widely applied, further improving the wiring density and signal transmission performance of circuit boards.

(2) 3D Packaging and System Integration Becoming the Mainstream

To meet the requirements of electronic products for multi - functionality and high - performance, 3D packaging technology will gradually become the mainstream in the SMT field. Through 3D packaging, more functional modules can be integrated in a limited space, improving the performance and reliability of products. In addition, System - in - Package (SiP) technology will also be further developed, integrating multiple chips, passive components, etc. in one package to achieve system - level functional integration.

(3) Continuous Improvement of Intelligence and Automation Levels

The wave of Industry 4.0 and intelligent manufacturing is sweeping across the entire electronic manufacturing industry, and the SMT production process will also accelerate its development towards intelligence and automation. Future SMT equipment will have more powerful functions such as intelligent identification, automatic correction, fault warning, and remote monitoring, and can achieve automated control and optimized management of the production process, improving production efficiency, reducing labor costs, and minimizing human errors.

In conclusion, SMT technology is facing broad development opportunities globally, as well as challenges in technological upgrading and market competition. In China, enterprises like FASTPCBA, with their advanced technologies, high - quality services, and strong innovation capabilities, have injected new vitality into the development of the SMT industry. It is believed that in the future, with the continuous progress of technology and the continuous development of the market, the SMT industry will embrace an even more brilliant future.